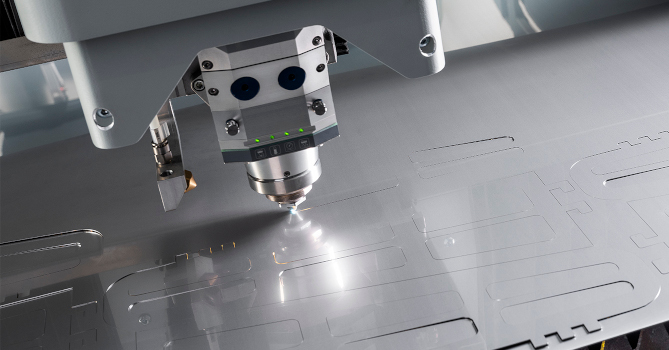

Category: Flat Laser

-

Cutting Metal with Fiber Lasers: Understanding the Pros and Cons of Different Assist Gases for Carbon Steel, Stainless Steel, and Aluminum

Cutting metal with a fiber laser requires an assist gas to blow away molten material and debris. Oxygen is commonly used for cutting carbon steel due to its ability to quickly react with iron, resulting in a faster cutting speed. However, oxygen can cause oxidation and dross formation, which can lower the quality of the…

-

Optimizing Laser Cutting Operations with Nitrogen Generation and High Pressure Dry Air Systems

Nitrogen generation and high pressure dry air systems are two options that laser cutting operators can choose from to improve their cutting processes. Nitrogen generators are commonly used as assist gases in laser cutting operations due to their ability to produce high-quality cuts and reduce oxidation. They work by filtering atmospheric air to produce high-purity…

-

Why Your Fabrication Job Shop Should Consider a 6-10kW Laser for Cutting Efficiency

When a fabrication job shop is considering purchasing a new laser, it is important to carefully evaluate the power requirements needed to meet the demands of the shop’s production needs. In many cases, a laser with a power output between 6-10kw is ideal for most job shop applications. Firstly, a laser with a power output…