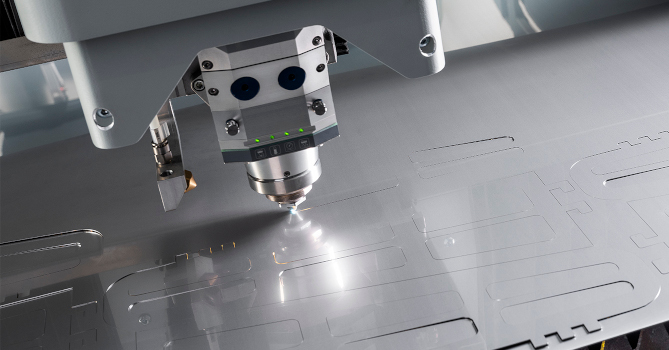

Cutting metal with a fiber laser requires an assist gas to blow away molten material and debris. Oxygen is commonly used for cutting carbon steel due to its ability to quickly react with iron, resulting in a faster cutting speed. However, oxygen can cause oxidation and dross formation, which can lower the quality of the cut. It can also cause warping and lead to a rougher edge. In contrast, nitrogen can provide a smoother edge, but it has a slower cutting speed and may require higher laser power.

When cutting stainless steel, high pressure dry air is often used as an assist gas because it does not react with the metal and does not cause oxidation or dross formation. It can also provide a clean cut with minimal discoloration. However, it has a slower cutting speed compared to nitrogen and may require higher laser power. Nitrogen can also be used for cutting stainless steel, but it can lead to a rougher edge due to its slower cutting speed.

For cutting aluminum, nitrogen is often the preferred assist gas due to its ability to provide a clean cut with minimal discoloration. It can also prevent the formation of an oxide layer on the surface of the metal, which can occur when using oxygen. However, nitrogen has a slower cutting speed and may require higher laser power compared to oxygen.

The choice of assist gas also depends on the thickness of the metal being cut. Oxygen is typically used for cutting thicker carbon steel, while nitrogen is preferred for thinner material. Nitrogen can also be used for cutting thicker stainless steel and aluminum, but it may require higher laser power to achieve the same cutting speed as oxygen.

Another factor to consider is the cost of the assist gas. Oxygen is generally less expensive than nitrogen, but it can lead to higher maintenance costs due to the need for regular cleaning to prevent oxidation and dross buildup.

In addition to the choice of assist gas, other variables can affect the quality of the cut, such as the focus position of the laser beam, the speed of the cutting process, and the type of nozzle used. Therefore, it is important to conduct thorough testing to determine the optimal assist gas and cutting parameters for each specific application.

In summary, the advantages and disadvantages of different assist gases for cutting metal with a fiber laser depend on the type and thickness of the metal being cut, as well as other variables such as cost and maintenance requirements. Oxygen is often preferred for cutting thicker carbon steel, while nitrogen is preferred for thinner material and for cutting stainless steel and aluminum. High pressure dry air can also be used for cutting stainless steel. It is important to conduct thorough testing to determine the optimal assist gas and cutting parameters for each specific application